Luxury & Craft

Manual Production and Quality Monitoring System

Mulberry is a luxury fashion company founded in the United Kingdom in 1971, known internationally for its leather goods.

Mulberry is a luxury fashion company founded in the United Kingdom in 1971, known internationally for its leather goods.The company has invested in PlantRun systems for its two UK manufacturing sites at Chilcomptom and Bridgewater. The decision to go with PlantRun was made after extensively researching the market.

Before ordering the systems Rob Billington Group Production and Sourcing Director commented;

“We’ve been looking into alternatives to the PlantRun system and it’s clear that your system is the closest match to our requirements”

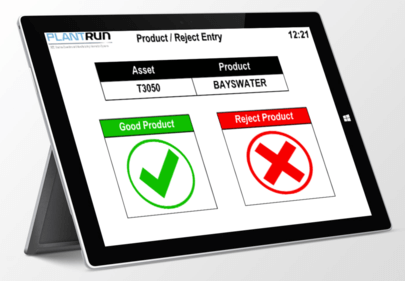

The systems monitor quality check stations at the end of each production line. Quality controllers check each product and use on screen buttons on a tablet interface to indicate Pass or Reject. Selecting ‘Reject’ switches to a second screen display allowing a reason for rejection to be selected from a grid of buttons.

Each time ‘Pass’ is selected increments a product count. Data from each tablet is processed in real-time, eliminating the need for manual data collection. Production information becomes available immediately on PCs, tablets and smartphones for reporting, analysis, trending etc. using the system built in tools. Data can also be exported for use in third party reporting tools such as MS Excel and Crystal Reports.

Each time ‘Pass’ is selected increments a product count. Data from each tablet is processed in real-time, eliminating the need for manual data collection. Production information becomes available immediately on PCs, tablets and smartphones for reporting, analysis, trending etc. using the system built in tools. Data can also be exported for use in third party reporting tools such as MS Excel and Crystal Reports.Tablets provide an ideal operator interface for manual operations where there is no need to interface to a machine or asset. Wireless connection also makes installation even more straight forward than a standard PlantRun system.

PlantRun Display Node enables target and actual production to be displayed at the end of each line on large screen TV displays to inform and motivate staff. Display Node allows any data from the system as well as MS Powerpoint slides or website URLs.

Since implementation Tom Breingan, UK Production Planning Manager commented;

"We chose PlantRun as a shop floor system to show our craftspeople how their production lines are performing on a minute by minute basis. It also gives Managers and Supervisors a snap shot of production performance at the same time. We have added additional displays along the way to show different business KPI’s.

We’ve found that the introduction of PlantRun has motivated our staff and provides a focus point for all staff involved with production. Adding the moving target for each production line was a great addition and Tascomp have always been more than helpful when setting up the things we need and they completely understand our requirements."

If you have a similar requirement contact us to discuss how we can help.